Arthur D. Little, William H. Walker, and Warren K. Lewis

In the late 19th century, Little, Walker, and Lewis worked to define chemical engineering as a distinct field with a special training method.

The notion of a new kind of engineer―a chemical engineer―who understood both chemical processes and mechanical equipment was broached in England around 1880.

The idea first took firm root, however, in the United States in the 1890s. Arthur D. Little, William H. Walker, and Warren K. Lewis were among the leaders of the movement to create the new profession of chemical engineering.

Chemical Engineering as a Profession

According to the British engineer George E. Davis, the ideal chemical engineer could move from industry to industry, mixing and matching the various operations that the American Arthur Little (1863–1935) was later to call “unit operations.” Little first used this term in a 1915 report to the president of the Massachusetts Institute of Technology (MIT), where the curriculum in “chemical engineering” dated from 1888. The first degrees in this field in the United States were given at MIT in 1891, although the content of the original courses still centered on industrial chemistry and mechanical engineering, without the characteristic unit-operations laboratory. William Walker (1869–1934), Warren Lewis (1882–1975), and Little were among the leaders who defined chemical engineering as a separate profession with a distinct approach and training method.

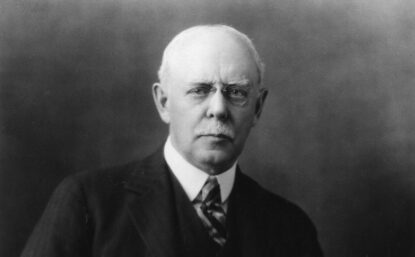

Arthur D. Little, Inc., and the American Chemical Industry

A native of Boston, Little majored in chemistry at MIT before the advent of chemical engineering and was the editor of the college newspaper, The Tech, an experience that prepared him for his role as a spokesperson for chemical-engineering education, industrial research, and the American chemical industry. His first jobs made him an expert in the new sulfite process for making paper, and in 1886 he and a coworker, Roger B. Griffin, set up a consulting company whose successor, Arthur D. Little, Inc., prospered as an independent company for more than a century. (In 2002 it became part of the Paris-based consulting firm Altran.)

Seven years after Little and Griffin founded their company, Griffin died tragically in a laboratory explosion. Little continued as a consultant, becoming involved in two new synthetics—cellulose nitrate and cellulose acetate—that were being used for photographic film and woven fabrics. The reluctance of American financiers to undertake ventures in this new technology—opportunities that were instead seized by Europeans starting up plants in the United States—prompted Little to mount a writing and speaking campaign directed at financial, political, and educational leaders to encourage the nascent American chemical industry. From an early date Little also preached against heedless industrial practices, referring ominously to “the handwriting on the wall” for a society that would destroy its own environment.

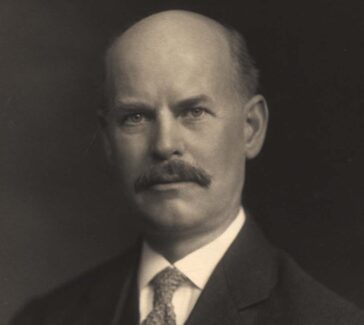

Little and Walker: A Partnership

In 1900 Little formed a new partnership with William Walker, a young MIT chemistry instructor who had graduated from Pennsylvania State University with a bachelor’s degree in chemistry and who held a doctorate in organic chemistry from the University of Göttingen in Germany. Walker was soon recalled to MIT to reform the chemical-engineering curriculum—with Little in the background gaining approval and funds for various initiatives to bring industry and education closer together.

In 1908 MIT’s Research Laboratory of Applied Chemistry began operations. Here chemical-engineering students worked on real industrial problems presented by various chemical companies, which also supplied fellowships.

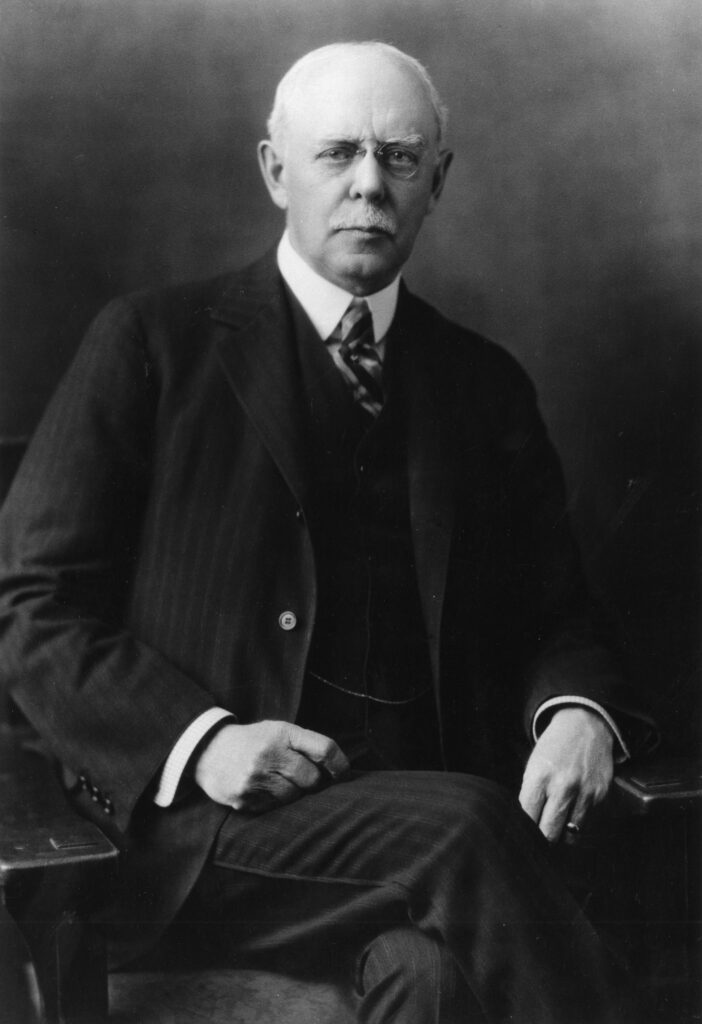

Lewis Joins Chemical Engineering at MIT

In 1908 Warren Lewis, a young graduate of MIT’s chemical-engineering program with a PhD in organic chemistry from the University of Breslau (then part of Germany and now the University of Wrocław in Poland), joined the teaching staff at MIT. He contributed a great deal to the program with his ability to view engineering problems theoretically and mathematically and with his memorable teaching style, which was sometimes described as bombastic but nonetheless endeared him to students.

In 1916 three plant-based stations of the School of Chemical Engineering Practice were inaugurated, thus enabling students to gain more hands-on experience by spending eight weeks at one of the stations under the supervision of an MIT faculty member. Meanwhile, under Lewis’s guidance, teaching in the fundamental unit-operations course had become highly quantitative. One result of this course, The Principles of Chemical Engineering (1923) written by Walker, Lewis, and William H. McAdams, became the standard text for chemical-engineering instruction for decades.

Later Achievements and Recognition

Shortly after publication of the book, Walker returned to consulting. From his faculty position, Lewis also maintained close connections with industry, consulting most frequently for Standard Oil Company of New Jersey (now ExxonMobil).

His most famous industrial contribution—in collaboration with his colleague Edwin R. Gilliland—was fluidized-bed catalytic cracking of petroleum, which solved many of the problems posed by the catalytic cracking process developed by Eugene Houdry and played a large part in supplying the vast quantities of gasoline needed during World War II.

In 1947 Lewis became the first chemical engineer to receive the Priestley Medal, the highest honor conferred by the American Chemical Society; he was also an elected member of the National Academy of Engineering.

For his contributions to the growth of American chemical industry, Little was awarded the prestigious Perkin Medal in 1931 by the Society of Chemical Industry, while Lewis received it in 1936.